SERIALIZED DISCRETE MANUFACTURING

A new standard for serialized discrete manufacturing data

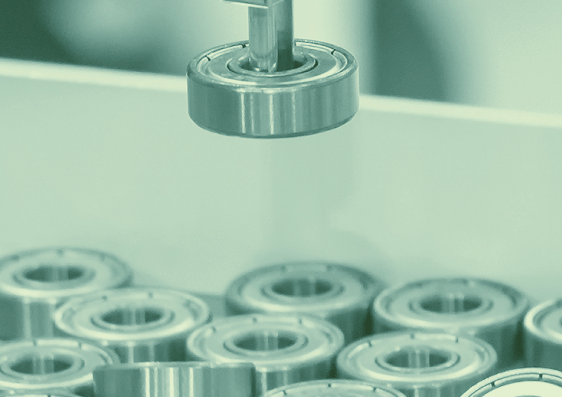

Ensure quality and traceability at scale with Rhize—the world’s first manufacturing data hub for serialized discrete manufacturing.

Traceability

Trace product history through each material, part, machine, and human interaction. Get an up-to-the-minute, moving picture of your entire operation.

Workflow Automation & Optimization

Workflow Automation & Optimization Define a near-infinite number of real-time events, then trigger specific business process automation workflows as soon as an event is detected.

Real-time Orchestration

Ingest and process data at every stage of your production lines. Get real-time monitoring of critical events, equipment status and material conditions to ensure assemblies meet strict quality standards every time.

Insights & Analytics

Know what’s currently happening in your operation across all serialized part production lines at every stage. Unlock decision-grade insights into complex data-driven relationships.

Custom App Development

Custom App DevelopmentRhize connects via single API to any kind of purpose-built application you want, from business intelligence platforms to advanced AI/ML models.

Quality Assurance

Achieve full visibility into and a better understanding of material, part and product quality by leveraging real-time insights.

Operational Efficiency

Minimize waste, reduce downtime and optimize each production step with data-driven insights made to scale with your operation.

Scheduling

Simplify complex production scheduling and assembly with a Gannt-based view informed by a comprehensive ISA-95 schema.

Transform serialized production with real-time data

No matter the complexity of your serialized production, Rhize can help you build solutions that improve your operation, from quality assurance to equipment efficiency to complex scheduling and beyond.

KEY BENEFITS

Take control of the entire operation

Contextualize data from all sources

ISA-95 schema allows you to define equipment, materials, parts, and process data, and then use it to identify event-based relationships between everything – at scale, all based on unique business rules.

Streamline production processes

Empower your entire operation with real-time, standardized data that makes it easy to replicate and scale complex production processes. Stay ahead of your competition, and stay compliant with relevant quality regulations with a fit-for-purpose solution.

Scale with complete confidence

Unlock a broader and deeper understanding of what’s happening—from raw material to completed assembly, historically and in real-time. Expand operations while aligning development and innovation cycles more closely with the pace of production.