Is the problem with the standard or with the architecture?

The last few years have resurrected old debates about the ISA-95 standard. Is it useful? Is it viable? Disagreement happens, but in our decades of work implementing manufacturing data infrastructure and MES/MOM systems, we can’t recall a time when the debate has been so polarized. Meanwhile, we don’t think the conversation is really about the standard at all—it’s about how people view the standard in relation to their attempts to implement digital transformation.

The debate is always framed in absolute terms: “Is ISA-95 still a relevant, useful standard for manufacturing?” To such a broad, overly general question, the answer is a resounding “yes.” But what if we ask something more specific, like “Is ISA-95 a viable option for <my_architecture_paradigm>?” For many architecture paradigms, the answer is probably “no.”

So, how can the standard be useful in general but not viable in particular? The answer lies in the details of the chosen implementation and architecture. Let’s start by examining what ISA says about the standard.

ISA-95: does what it says on the tin

ISA-95 is explicit about its scope and goals:

- Scope: Define, in detail, an abstract model of the enterprise, including manufacturing control functions, business functions, and information exchange.

- Goal: Reduce the risk, cost, and errors associated with implementing the interfaces between control and enterprise systems.

Given that, it’s hard to argue that the standard is suddenly irrelevant to manufacturing. Why? Because it fulfills what it claims to do:

- What it does: Presents the entities and relationships in an abstract model that contains the most complete definition of modern manufacturing.

- What that achieves: Provides the model as a common language that, if properly implemented, reduces the risks, costs, and errors of implementing an MES/MOM application layer.

What ISA-95 doesn’t tell you is how to implement the model, what architecture to use, or how to make your specific business processes work with the model. So, is the standard useful for your operation? The answer is “yes” only if it meets certain conditions:

- You can implement your specific instance of the abstract model (not every manufacturing system contains every bit of the model)

- This implementation works with the architecture that you've chosen.

A failure at one of these points is where the limitations of ISA-95 show—but are these limitations of ISA-95 or of the implementation?

A data model must be complete

When an enterprise starts the long, arduous process of developing a series of applications for its MES/MOM system, it also develops a standard data model. It may not use a recognized standard, but the goal is still to create a standard definition that can be used everywhere (i.e. “scale”).

Small operations with simple problems can get away with an incomplete model. To scale, however, an enterprise’s data model must capture its complete ontology, the names and definitions of the categories, properties, and relations between the concepts, data, and entities for a specific domain. And the enterprise must capture this before it tries to create the applications that it will use for operations.

However, it’s extremely hard to create such a generic data model (if a team of experts doesn’t spend years beforehand), so bespoke models inevitably run into limitations, incompatibilities, and schema changes. These frustrations lead manufacturers to consider ISA-95.

But ISA-95 is still insufficient without the correct architecture.

The data is mostly irrelevant on its own. The events produced by the data are everything. Therefore, the architecture of an MDH must be event-driven, not data-driven.

The architecture must match the model

Most architectures—legacy and 4.0—use some sort of relational database to create the schema and store the instance of the model. Yet, because of a problem known as object-relational impedance mismatch, it’s very hard to model all of ISA-95 in a relational schema. The difficulty leads practitioners of these approaches to eschew ISA-95, branding it as “outdated” and “useless.” They see it as a rigid set of rules and complain that standards must be “frameworks.” This complaint arises not because the model is irrelevant to their work, but because they can’t implement it.

The thing is, though, ISA-95 is a framework, at least when implemented properly. Nothing in ISA-95 says, “To use this, you must adhere to absolutely everything without exception.”

Manufacturing Data Hub (MDH) architecture makes ISA-95 a reality

We’ve established two challenges:

- To develop scalable MES/MOM applications, you must first apply a full ontology (schema) of your manufacturing domain.

- Using ISA-95 with a relational DB is extremely difficult, and failure-prone when attempting to apply changes.

If those challenges all but rule out ISA-95 for legacy and Industry 4.0 architectures, how can the answer still be, “Yes, ISA-95 is viable?”

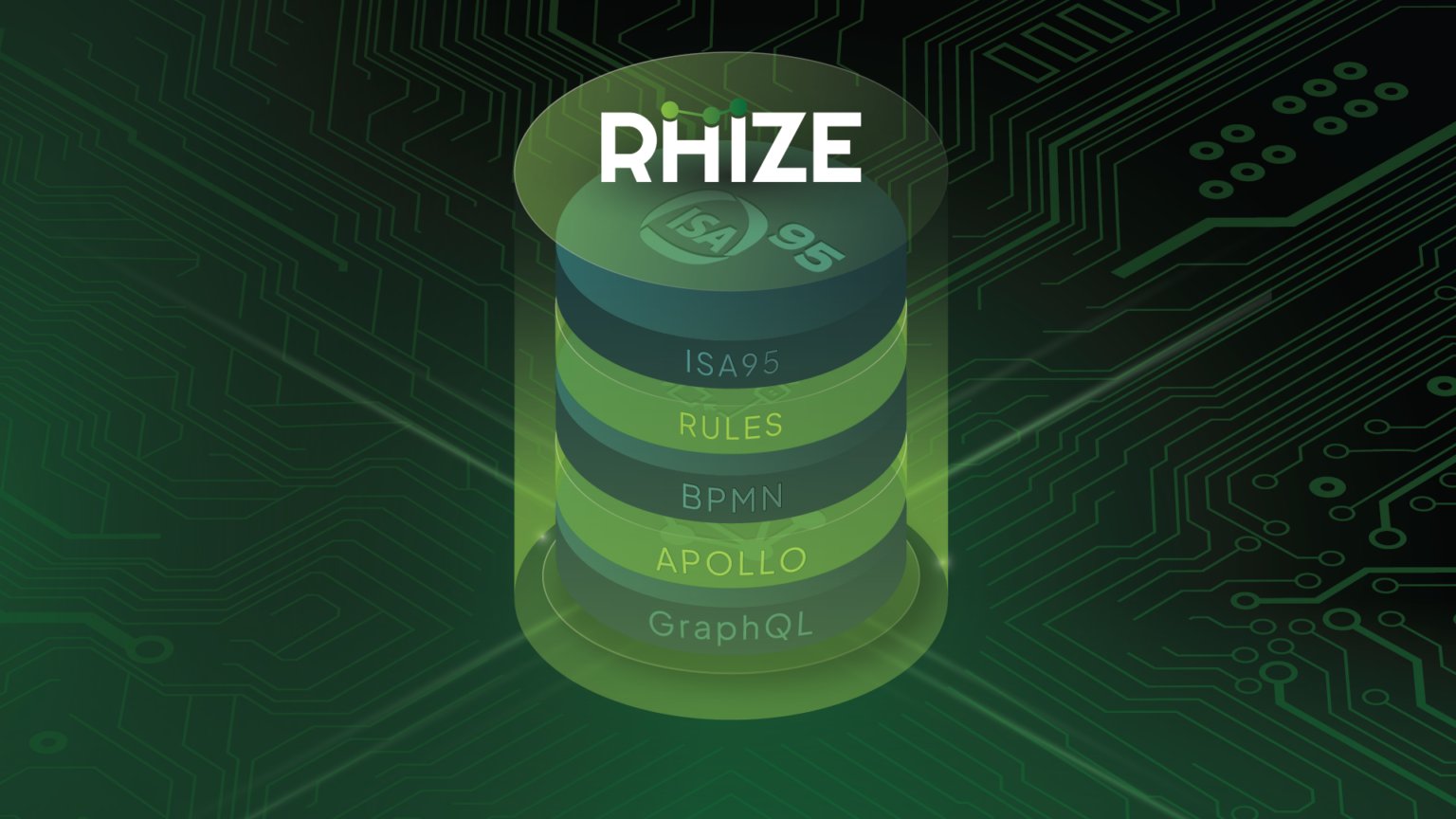

The answer is “yes” because it’s possible to deploy an ISA-95 ontology on a GraphQL native graph database. This architectural decision is at the heart of the Manufacturing Data Hub (MDH), which uses a knowledge graph that represents the ISA-95 standard as a schema in a set of nodes (entities) and edges (relationships).

So, how does an MDH fit the requirements?

- ISA-95 is, by definition, a full manufacturing ontology, so the challenge to provide a complete data model is overcome.

- Because a graph can be extended or mutated by adding a node or an edge, the schema can be changed to represent a new entity and its relationship to the existing schema, or to add a new relationship between existing entities. You can do this without degrading any instances or applications already deployed in the MDH.

Of course, a data model and interface that coheres with ISA-95 is only one component of the MDH architecture, which must also scale with the information flows of an operation of any size.

The ISA-95 standard is more relevant than ever

Yes, the ISA-95 standard is more relevant and useful than at any time in its history. In fact, its usefulness now goes beyond providing a vocabulary for level-3 and level-4 systems―ISA-95 now serves as a foundational data model for modern Manufacturing IT.

But that statement is true only if you use an architecture that can take advantage of the standard. If you aren’t, then ISA-95 probably isn’t useful for you. But don’t point your finger at the standard: change your frame of reference and question your approach.